The electric motor core is at the center of the significant change that the electric vehicle (EV) industry is experiencing. As demand for EVs surges, advancements in motor core technology are playing a critical role in improving efficiency, performance, and overall vehicle range. These innovations are helping drive the future of sustainable transportation, making electric vehicles more accessible and viable for consumers worldwide.

What Are Electric Motor Cores?

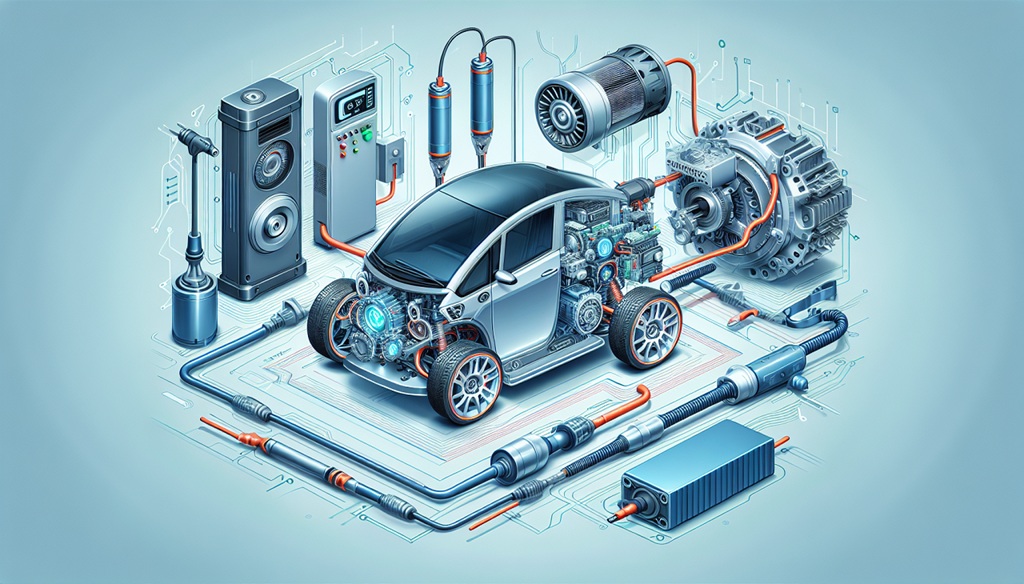

The electric motor core is a key component of an EV’s powertrain. It consists of laminated sheets of electrical steel, which work together to form the magnetic field necessary to generate rotational power. The core’s efficiency directly impacts how effectively the electric motor converts electrical energy into mechanical energy to propel the vehicle.

These motor cores are built to minimize energy losses, which can otherwise reduce motor performance and efficiency. The advanced designs of motor cores are enabling electric motors to operate more efficiently, resulting in longer driving ranges, improved acceleration, and a reduction in the overall weight of the vehicle.

Technological Advancements in Motor Core Design

Recent advancements in motor core design are significantly enhancing the capabilities of electric vehicles. New high-performance materials, such as silicon steel alloys and specialized electrical steels, are being used to improve the core’s magnetic properties. These materials enable increased energy efficiency, resulting in lighter and more potent motors.

Additionally, manufacturing methods have advanced.For example, high-speed stamping processes and laser cutting enable the production of thinner, more precise laminations, which further reduce energy losses and improve motor efficiency. Motor lamination manufacturers, such as Gator, are at the forefront of this innovation, creating high-quality laminations that meet the growing demands for precision and performance. This precision manufacturing is allowing companies to create more reliable, higher-performing motor cores at a lower cost.

Impact on EV Performance and Efficiency

The impact of improved motor cores on EV performance cannot be overstated. In traditional internal combustion engine (ICE) vehicles, much of the energy is lost as heat. Electric motors, in contrast, are inherently more efficient, and with the continued development of motor cores, they are becoming even better at converting electrical energy into usable mechanical energy.

A more efficient motor core helps extend the range of electric vehicles, allowing them to travel further on a single charge. This is especially important as automakers strive to increase the competitiveness of EVs by offering longer-range models that rival the performance of conventional vehicles.

Moreover, electric motors with advanced cores are helping reduce the size and weight of the motor while maintaining or even increasing power output. Lighter vehicles are not only more energy-efficient but also offer better handling and performance, making them more attractive to consumers.

Improved Thermal Management

Another critical benefit of new motor core technologies is better thermal management.During operation, electric motors produce heat, which may compromise their longevity and efficiency. Modern motor cores are designed to handle heat more effectively, preventing overheating and extending the motor’s lifespan.

Materials with higher thermal conductivity provide more effective heat dissipation, guaranteeing that motors continue to operate at their best even under demanding circumstances like long-distance driving or fast acceleration. This improved heat management is especially beneficial for high-performance EVs and those used in demanding environments, like heavy-duty electric trucks or delivery vehicles.

The Future of Motor Cores in EVs

The future of motor cores in EVs is bright, with ongoing research focused on developing even more efficient and cost-effective solutions. Researchers are exploring the use of rare-earth-free materials, which could reduce costs and reliance on scarce resources. Additionally, solid-state motor cores, made from next-generation materials, hold the potential to significantly increase energy density and reduce weight, further enhancing the performance of electric motors.

As electric vehicle adoption continues to grow, motor core technology will be central to meeting the performance, efficiency, and cost demands of the market. The development of advanced motor cores will help power the next generation of electric vehicles, enabling them to offer even greater efficiency, power, and range.

Conclusion

Electric motor cores are revolutionizing the powertrains of electric vehicles, improving efficiency, performance, and driving range.Improvements in design, materials, and manufacturing techniques are making motor cores lighter, more dependable, and more efficient. As these innovations continue to evolve, they will play a key role in the widespread adoption of electric vehicles, contributing to a more sustainable and eco-friendly transportation future.